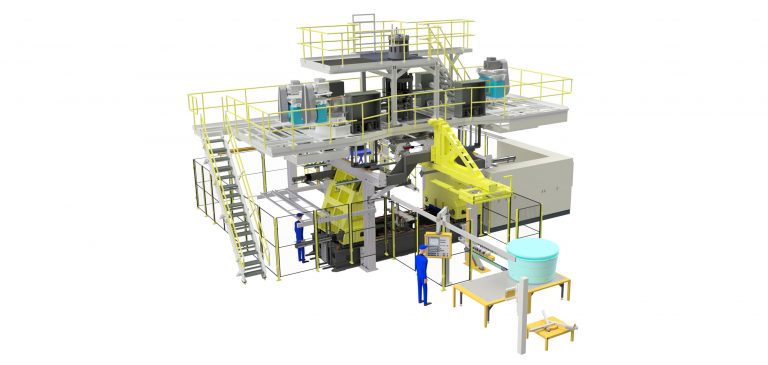

HIGH PERFORMANCE MULTI-LAYER COEXTRUSION BLOW MOLDING MACHINE

The machine type GBM S 1000 LD/ S 1500 LD covers the range of large-volume packaging vessels. Here it is not only possible to produce a 220 liter drum, but also a 1,000 liter IBC. In this volume range however, not only packaging containers can be manufactured, but even technical blow-mold articles such as fuel tanks or products for road safety can be created individually here.

CLAMPING UNIT

Both mold platens are guided by 4 runner blocks with a linear guiderails system on a closed frame. The closing and opening motions of the mold platens are done hydraulically with proportional valves, controlled via digital sensors and the machine control. The movement of each plate is controlled separately, which allows synchronous or asynchronous movements.

OUR COEX AND BI-EX ACCU-HEADS FROM 25 UP TO 80 LITERS:

„ Ideal for products used in the field of industrial packaging technology (drum, IBC).

ACCU-HEAD

The RIKUTEC Coextrusion Accumulator Head works to the „first in/ first out“ system. The hydraulically driven injection piston is controlled by means of a proportional valve (speed control). The piston for controlling the wall thickness is controlled by means of a separate circuit including a control valve.

Upon product requirement different systems for partial wallthickness control can be offered.

EXTRUDER

Extruder with grooved and cooled infeed bushing and barrier screw with mixing tip. For processing HMW-HDPE as powder or pellets.